Coated paper

that protects your food

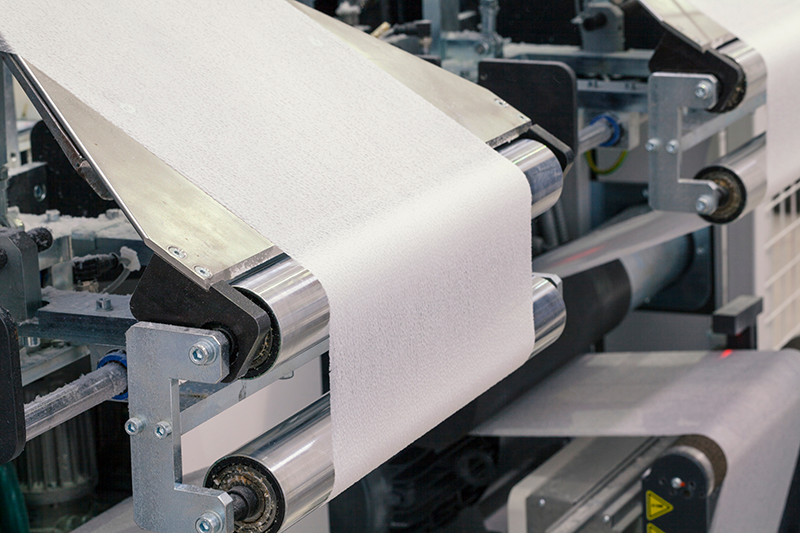

Our Micropap® and Végépap® coated paper ranges are complex and high-tech products, resulting from many years of research and development within Groupement MICROPAP.

What is the purpose of coating ?

Our coating technique enables mineral or vegetable wax to be deposited evenly and in a controlled manner on to the paper’s surface. The paper can be coated on one or both sides and the coating can be opaque or not. The coating gives the paper mechanical properties and acts as a barrier against water vapour.

The properties of this barrier are determined by the type of wax and paper and the coating process, and are selected by the converter depending on the intended use: moisture barrier, controlled permeability for maturing live food products such as cheese, etc.

Designed to perfectly meet the needs of each product, our coated paper ranges help to:

- preserve and optimise the product’s organoleptic properties;

- showcase the product;

- mature the product;

- ripen the product in the final stage;

- la maîtrise de la freinte ;

- la garantie et la sécurité de la consommation jusqu’à la date de durabilité minimale (DDM) ;

- protect the product during transport and distribution.

A solution to the challenges of today

Coated paper with a proven track record in food safety

Mineral and vegetable waxes have undeniable advantages for food safety which have been recognised and valued for decades. Their high stability at room temperature and their inertness has proven their safe use in contact with food.

- Règlement (CE) n°1935/2004 du parlement et du conseil du 27 octobre 2004 concernant les matériaux et objets destinés à entrer en contact avec des denrées alimentaires et abrogeant les directives 80/590/CEE et 89/109/CEE ;

- Règlement (CE) n°2023/2006 de la commission du 22 décembre 2006 relatif aux bonnes pratiques de fabrication des matériaux et objets destinés à entrer en contact avec des denrées alimentaires ;

- Fiche MCDA n°4 (01/01/2019) DGCCRF Aptitude au contact alimentaire des matériaux organiques à base de fibres végétales destinés à entrer en contact avec des denrées alimentaires

Des papiers enduits inscrits dans une logique d'innovation

- Our Micropap® and Végépap® paper ranges have minimal environmental impact: they are made of virgin cellulose fibres from wood certified by the PEFC (Programme for the Endorsement of Forest Certification, which promotes sustainable forest management) and the FSC (Forest Stewardship Council).

- Les papiers Micropap® and Végépap®, qui peuvent être soit recyclés soit compostés, apportent leur contribution à la filière de traitement des emballages ménagers papier cartons.

Trends

Groupement MICROPAP manufacturers are currently exploring a number of avenues to improve the Micropap® et Végépap® ranges, respond to current trends and anticipate future needs. The main current trends are as follows:

- Return to using paper;

- Single-material;

- Écoconception : allégement du support papier, réduction poids d’enduction, développement enduction végétale, …) ;

- Reduction in packaging weight.

Components

The wax

The generic term “wax” refers to the material deposited on the paper’s surface. It is authorised for use in contact with food.

Wax can be of mineral or vegetable origin:

The base material

Since its foundation, Groupement MICROPAP has made the choice to focus on paper: a natural, recyclable material, processed in France by companies with proven expertise.

The Micropap® and Végépap® coated paper ranges are made of virgin cellulose fibres from PEFC-/FSC-certified wood, guaranteeing sustainable resource management.

Brands

The benefits of Micropap® , the secret to its success® and Végépap®

- Suitable for contact with food (inertness).

- Barrier protection: inspired by biological membranes, the controlled permeability to water vapour regulates the exchange of gases while protecting the product. This essential quality helps to ripen cheese and mature meat.

- Water-repellent effect.

- Waterproof.

- Anti-stick: does not stick to food.

- Compostabilité : les tests réalisés en 2023 par le laboratoire d’analyses APESA {lien vers APESA} ont démontré la compostabilité industrielle du MICROPAP et du VEGEPAP selon la norme EN 13432.

MICROPAP®

The group's flagship product, Micropap® is a type of paper coated with mineral wax. It is a high-tech product offering high added value.

Composition :

- Support (fibres vierges de cellulose) : 32 ou 40 g/m2.

- Coating: on one or both sides, opaque or not.

Produit conforme à la réglementation française et européenne :

- Règlement (CE) n°1935/2004 du parlement et du conseil du 27 octobre 2004 concernant les matériaux et objets destinés à entrer en contact avec des denrées alimentaires et abrogeant les directives 80/590/CEE et 89/109/CEE ;

- Règlement (CE) n°2023/2006 de la commission du 22 décembre 2006 relatif aux bonnes pratiques de fabrication des matériaux et objets destinés à entrer en contact avec des denrées alimentaires ;

- Fiche MCDA n°4 (01/01/2019) DGCCRF Aptitude au contact alimentaire des matériaux organiques à base de fibres végétales destinés à entrer en contact avec des denrées alimentaires

Micropap®, un papier enduit innovant et recyclable.

Le Groupement MICROPAP est convaincu que le papier enduit a un rôle essentiel à jouer en tant que matériau, en répondant au besoin de RSE des entreprises. Il peut ainsi devenir une véritable alternative dans certains secteurs de l’agroalimentaire comme pour les confiseries, les barres chocolatées, en boulangerie, en sandwicherie, etc.

VÉGÉPAP®

Avec son enduction de cire végétale, le papier Végépap® a marqué un tournant pour les papiers à base d’enduction pour application alimentaire. Ses composants répondent à la demande croissante de produits issus de matières premières renouvelables et qui sont recyclables.

Composition :

- Support (fibres vierges de cellulose) : 32 g/m2.

- Double-sided coating of 9 grams with more than 90% of components of plant origin and from renewable sources.

Produit conforme à la réglementation française et européenne :

- Règlement (CE) n°1935/2004 du parlement et du conseil du 27 octobre 2004 concernant les matériaux et objets destinés à entrer en contact avec des denrées alimentaires et abrogeant les directives 80/590/CEE et 89/109/CEE ;

- Règlement (CE) n°2023/2006 de la commission du 22 décembre 2006 relatif aux bonnes pratiques de fabrication des matériaux et objets destinés à entrer en contact avec des denrées alimentaires ;

- Fiche MCDA n°4 (01/01/2019) DGCCRF Aptitude au contact alimentaire des matériaux organiques à base de fibres végétales destinés à entrer en contact avec des denrées alimentaires

Végépap®, un papier enduit novateur et séduisant

Végépap® paper was awarded the 2012 Packaging Oscar in the Flexible Packaging category, confirming its groundbreaking status. The jury praised its innovative development as part of a collective approach and the high-tech nature of the product.

Végépap® fulfils an important expectation of the food industry, as well as of consumers.

Recovery through composting according to standard EN 13432

Standard EN 13432 meets the objectives of Directive 94/62/EC on packaging and packaging waste, which aims to promote the prevention and recovery of packaging waste. It specifically refers to the recovery of packaging through industrial composting and defines the applicable test programme and evaluation criteria for acceptance of packaging as compostable.

Les exigences de la norme EN 13432

According to standard EN 13432, packaging is deemed compostable if all of its components are compostable, based on four criteria:

- composition: the standard defines the maximum values for volatile solids, heavy metals (Cu, Zn, Ni, Cd, Pb, Hg, Cr, Mo, Se, As) and fluorine which are acceptable in packaging materials;

- biodegradability: the acceptable biodegradability threshold is at least 90% and within a maximum time period of 6 months;

- disintegration: or the product’s capacity to break down through composting: after 12 weeks, at least 90% (by mass) of the packaging must pass through a 2 mm sieve;

- quality of the final compost and ecotoxicity: the quality of the final compost should not decline as a result of the packaging material added to the compost and must not be harmful to the environment. The standard requires that ecotoxicity tests are carried out based on germination tests and that product performance is higher than 90% of the performance of the corresponding control compost.

Les tests réalisés en 2023 par le laboratoire d’analyses APESA {lien vers APESA} ont démontré la compostabilité industrielle du MICROPAP et du VEGEPAP selon la norme EN 13432.

Le laboratoire APESA est un centre technologique en environnement et maîtrise des risques ayant pour objectif d’accompagner les entreprises et territoires dans leur transition environnementale et sociétale. A ce titre, la structure constitue un centre de ressource aux compétences multiples organisée autour de 4 offres de service : réglementation et prévention HSE, Création de valeur sociétale, éco-innovation et évaluation environnementale.

Le pôle valorisation de l’APESA est spécialiste depuis plus de 20 ans des procédés biologiques de valorisation et de traitement : la méthanisation, le compostage, le traitement des effluents et la biodégradabilité des plastiques et emballages.